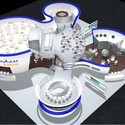

DÜSSELDORF, Germany — Oct. 27, 2010 — At K 2010, Hall 6, Stand D42, SABIC is showcasing new technologies, expanded capabilities and strong customer relationships that comprise its theme for the show: Culture of Innovation. A key focus is SABIC’s sustainability strategy, underscoring the company’s commitment to addressing worldwide sustainability issues – including energy and greenhouse gas reduction, water conservation and material efficiency. The SABIC stand features an impressive array of materials from its broad and growing portfolio that enable breakthrough applications across major growth sectors such as healthcare, automotive, electronics, packaging, film and alternative energy. View more and related images

Sabic Innovative Plastics

DÜSSELDORF, Germany — Oct. 27, 2010 — SABIC Innovative Plastics launched a new portfolio of specialty resins and compounds that can optimize the performance, lifespan and aesthetics of light-emitting diode (LED) retrofit lighting. These materials include non-brominated, non-chlorinated flame-retardant (FR) Lexan* polycarbonate (PC) resin and new white LNP* Konduit* thermally conductive compound for LED heat sinks, which adds style to outstanding heat dissipation for extended bulb life. One hundred and thirteen years after the invention of the light bulb, SABIC Innovative Plastics is developing solutions for the latest technological milestone in the evolution of lighting – with materials that promote adoption of these energy-efficient, long-lasting solutions – one of the broadest offerings for LED lighting customers on the market today. View more and related images

PITTSFIELD, Mass.— Oct. 21, 2010—SABIC Innovative Plastics today launched three new sustainable additions to its Valox* ENH resin series that deliver advanced flame retardance (FR) together with outstanding mechanical and electrical performance to the electrical and electronics (E/E) industry. These innovative materials help customers comply with global environmental regulations, including the European Union (EU) Waste Electrical and Electronic Equipment (WEEE) directive that is now also being applied in Korea and China. The expansion of the Valox ENH resin family is the result of SABIC Innovative Plastics’ ongoing focus to provide an ever-broadening portfolio of validated, sustainable materials to customers. View more and related images

PITTSFIELD, Mass.— Oct. 13, 2010 — SABIC Innovative Plastics today announced that it is adding state-of-the-art specialty polypropylene (PP) compounding to its Bay St. Louis, Miss. site in the first quarter of 2011. The site will use its existing infrastructure and adopt new processes to produce SABIC® PP compounds and SABIC STAMAX® long glass fiber-reinforced PP composites. Adding specialty PP to the site’s compounding capabilities enables the company to provide a broader range of high-performance materials to its customers in North America and to help satisfy demand for specialty compounds – which is a market recovering fast from the recent downturn. Investment in this highly automated and technologically sophisticated process supports SABIC Innovative Plastics’ commitment to meeting both automotive OEM needs for lightweight, high-performance materials that can significantly reduce fuel consumption and emissions vs. competitive products, and non-automotive needs in key segments such as fluid handling and appliance. View more and related images

PITTSFIELD, Mass. — Oct. 8, 2010 — SABIC Innovative Plastics’ leadership in developing materials that reduce system costs and respond to its customers’ sustainability needs has resulted in another landmark achievement: an expanded portfolio of Geloy* polycarbonate/acrylonitrile-styrene-acrylate (PC/ASA) resin blends that open new opportunities for key market sectors. Originally developed for the automotive industry to deliver improved mechanical performance and extreme weatherability, SABIC Innovative Plastics’ high-performance Geloy blends now comprise a robust new offering with specialized grades for broad use in healthcare, consumer electronics and electrical applications. This new advanced blending exemplifies the company’s 75-year pioneering work in engineering thermoplastic breakthroughs to meet always-shifting customer and market needs. View more and related images

PITTSFIELD, Mass. — Oct. 1, 2010 —To solve the challenges in creating complex, multi-part connectors, SABIC Innovative Plastics has developed specialized grades of its workhorse Ultem* resin to drive forward the development of highly cost-effective, one-piece molded connector designs. These unique materials can be precisely tailored to specific wavelengths and offer attenuation control, extreme high heat resistance and dimensional stability for accurate fiber alignment. This innovative new solution is intended to reduce connector costs by up to 20 percent, accelerate fiber installation and provide exceptionally long service life. SABIC Innovative Plastics’ continued investment in new fiber-optic-tailored technologies will help customers in this high-tech industry extend their reach across multiple strategic geographies worldwide. View more and related images

PITTSFIELD, Mass. — Sept. 29, 2010 — SABIC Innovative Plastics today announced that Chiangyu Electric, a leading Chinese wire and cable manufacturer and long-term customer, is helping to lead the rapid growth of Flexible Noryl* resin, a polyvinyl chloride (PVC) and halogen-free, flame retardant alternative for wire cables into high-end direct current (DC) charger and data cables. Producing ultra-white, custom-colored cables from this high-end product, Chiangyu Electric can now offer consumer electronics OEMs fashionable new alternatives to traditional black and gray cables. SABIC Innovative Plastics’ ongoing investment in innovative technologies and sustainable solutions is enabling customers in the dynamic consumer electronics industry to keep pace with changing aesthetic trends and heed the call for ever-improved performance while meeting tough, global requirements for environmental protection. View more and related images

CARTAGENA, Spain — Sept. 23, 2010 — Launching a new chapter in the history of one of its most renowned materials, SABIC Innovative Plastics today cut the ribbon at its new Ultem* polyetherimide (PEI) resin production facility here in Cartagena. This much-anticipated event marks a 35 percent increase in Ultem resin capacity for European and global customers. The state-of-the-art 300 million euros facility, which is SABIC Innovative Plastics’ second Ultem resin plant, will provide customers with higher supply dependability. The plant also encompasses scalable capacity for producing ultra-high-performance Extem* resin grades and specialty intermediates (anhydrides). Proprietary process chemistry and cutting-edge manufacturing technologies will improve operating reliability and flexibility while minimizing the environmental impact of by-products. This major investment demonstrates the company’s unyielding commitment to reliable, scalable supplies of its Ultem and Extem resin grades, whose outstanding performance is driving ever-greater demand from global customers. View more and related images

PITTSFIELD, Mass. — Sept. 20, 2010 — At the Aircraft Interiors Expo Americas, Sept. 14-16, 2010, SABIC Innovative Plastics have launched a new breakthrough technology for semi-structural aircraft interior parts featuring its high-flying Ultem* polyetherimide (PEI) resin. New Ultem composite aerospace board (CAB) sheets, co-developed and manufactured with Crane & Co., the global leader in specialty paper, provide a superior alternative to thermoset aramid fiber-reinforced honeycomb composites. The Ultem CAB sheets can be quickly thermoformed, offer a broad range of high-performance properties, are recyclable, and offer great potential to be refurbished with a newly developed decorative film layer while still meeting Federal Aviation Administration (FAA) requirements to extend useful life. The sheets are currently being trialed by a major airline. Together with the expertise of Crane, SABIC Innovative Plastics has launched yet another technology that delivers a cost-effective solution to the global aircraft industry. View more and related images

BRIGHTON, Mich. — Sept. 13, 2010 — Insulgard*, the industry leader in architectural security products, today announced a new window system that can protect emergency and security workers from the battering of hurricane- and tornado-strength winds, ballistic impacts and other threats. This state-of-the-art protection system combines Insulgard Security Products’ TH600 aluminum architectural framing system, TOR-GARD glazing material and Lexan* sheet to meet Federal Emergency Management Agency (FEMA) 361-2008 requirements for debris impact resistance, as well as UL® 752 specifications for security-ballistic protection up to level 8. Potential applications include 911 call centers, police and hospital emergency facilities, utility control centers and critical government infrastructure. Insulgard’s investment in security technologies provides customers with new ways to preserve and protect emergency professionals and property. View more and related images